Michaela Fousova

UCT Prague, Czech Republic

Title: Metallic 3D-printing for orthopedic surgery: question of surface and cell compatibility

Biography

Biography: Michaela Fousova

Abstract

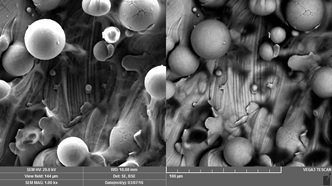

Metallic 3D printing is gaining more and more attention in these days and is gradually becoming a part of industrial production. A lot of metals and alloys can be processed already and there are more than five methods being intensely studied and improved. Application fields of this technology are very wide as almost any shape and design can be achieved. One of the most important fields is biomedicine. With 3D-printed biocompatible metals of desired shape and structure, bone defects can be successfully treated. Although bone structure with gradient porosity can be mimicked, mechanical properties can be adjusted to meet natural properties of the treated bone and osseointegration can be promoted. There are still some drawbacks needing to be solved. Especially in the case of porous structures, there is a problem of unmelted powder particles (being the material input) adhering to the final surface. These particles are harmful for several reasons. Not only they have a negative impact on mechanical performance (particularly fatigue life) and tribological properties, but they might also loosen into the body and set off an inflammatory reaction. Therefore, for biomaterials, surface quality and properties are of a particular importance. Our work focused on titanium alloy Ti6Al4V and its surface morphology and cell compatibility when prepared by 3D printing technology. Although biocompatibility of this broadly used alloy is well known, the interaction with biological environment may be affected by the 3D printing process. For this purpose, samples prepared by two most frequent metallic 3D printing methods – Selective Laser Melting (SLM) and Electron Beam Melting (EBM) were characterized in the as-printed state. Comparison of surface morphology and chemistry has been made. To assess cell compatibility contact in vitro tests were performed.

Recent Publications:

1. Fousová M et al. (2017) Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process. Journal of the Mechanical Behavior of Biomedical Materials. In press.